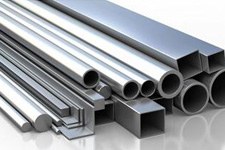

Tantalum alloy Tubes and Pipes

Tantalum alloy Tubes and Pipes

Nippon Titanium provides our customers superior tantalum and tantalum alloy seamless tubes. Less likely to fail than typical welded tubing, our process starts by piercing large diameter billets and forging the tubes down to your required dimensions. This eliminates weak spots in the products that could fail due to cracking, holes or tearing. Additional we can perform an eddy current test to detect leaks and pressure test the tubes to ensure there are no leaks.

In general, tantalum has excellent corrosion resistance and is often used in chemical processing equipment. To enhance the performance of the metal, Nippon Titanium recommends using our seamless tantalum 2.5% tungsten tubing.

| Specification and Standard for tantalum alloy tubes and Pipes | ||||||||||||

| Products | Grades | Size | Standards | |||||||||

| Tantalum Seamless Tube/Pipe Tantalum Welded Tube/Pipe | Ta R05200(Unalloyed Tantalum), Ta R05240(Ta40Nb) Ta R05252(Ta2.5W), Ta R05255(Ta10W) | Diameter: 1.0-150mm Thickness: 0.2-5.0mm Length: 100mm- 12000mm | ASTM B521 ASTM F560 | |||||||||

| Tantalum and Tantalum Alloy Seamless Tube and Welded Tube Performance Comparison | ||||||||||||

| Products | Specification | Advantage | Disadvantage | |||||||||

| Tantalum Seamless Tube/Pipe | Usually suitable for the production of small batch but many specifications | 1)Can produce small specification tube and capillary tube. 2)Good flexibility, suitable for production of small batch but many specifications. 3)The performance of the whole tube is homogeneous. | 1)The uniformity of wall thickness is difficult to control. 2)Production leadtime is long and low yield. 3)Complex equipment and large investment. 4)Difficult to produce large diameter tubes. | |||||||||

| Tantalum Welded Tube/Pipe | Usually suitable for the production of small batch but many specifications | 1)The wall thickness is even and the inner surface quality is good. 2)High production efficiency and low cost. 3)Easy to produce large diameter tubing. 4)Short production leadtime 5)Easy to ontrol products' quality. | 1)Poor flexibility, not suitable for production of more specifications but fewer batches. 2)Weld seams are often the weak links. 3)It is difficult to clean the weld seam. 4)The ellipticity is not easy to control. 5)High requirement for the dimension precision of strip. | |||||||||

| Nippon Titanium provides following testing for tantalum and tantalum alloy tube/pipe: | ||||||||||

| Chemical Cmposition | Elongation | Pitting Corrosion Test | Flattening | Dimensional Inspect | ||||||

| Visual Inspection | Tensile and Yield | Hardness Test | Flaring | |||||||